When it comes to effective landscape irrigation, one of the key components that can significantly enhance water efficiency and coverage is the use of Rotary Nozzles. These innovative devices provide a targeted approach to watering, ensuring that every inch of your garden receives the moisture it needs while minimizing waste. However, selecting the right rotary nozzles and implementing them effectively can be a daunting task for many homeowners and irrigators alike.

Understanding the various types of rotary nozzles available, their unique features, and how they fit into your specific irrigation system is essential for achieving optimal results. From adjusting the spray radius to choosing the appropriate flow rate, each choice you make can influence the overall performance of your irrigation setup. In this guide, we will explore the top ten tips for choosing and using rotary nozzles effectively, helping you navigate the selection process and maximize the benefits these nozzles offer to your watering routine. With the right insights and practical advice, you can transform your irrigation strategy, saving both water and money while promoting healthy plant growth.

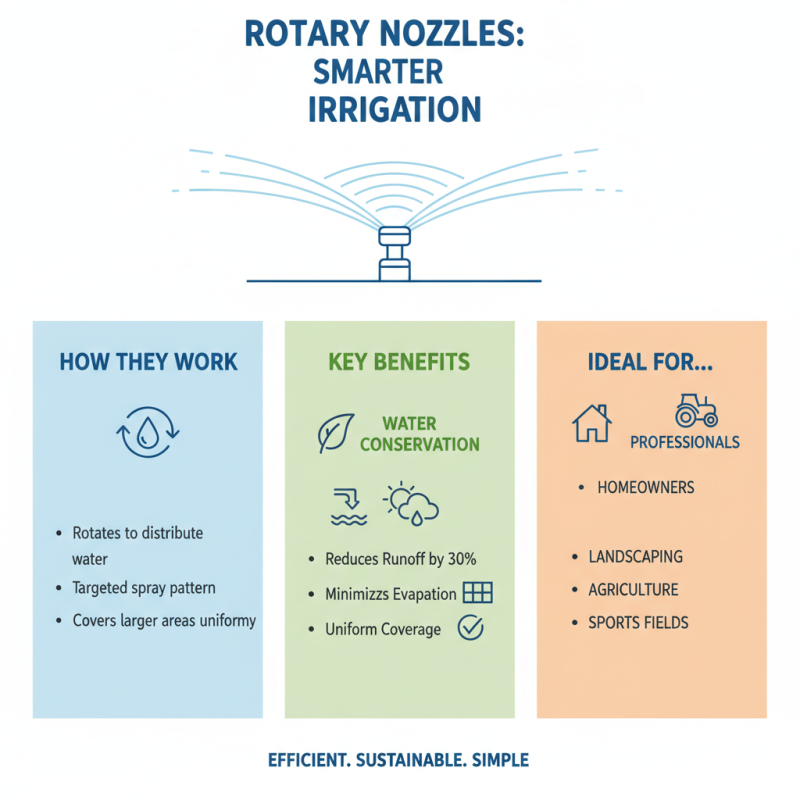

Rotary nozzles play a pivotal role in irrigation systems, offering efficient water distribution while reducing runoff and evaporation. Understanding these nozzles' basic functionality is crucial for both homeowners and professionals in landscaping and agricultural fields. Unlike traditional fixed nozzles, rotary nozzles operate by rotating and delivering a targeted spray pattern, which can cover larger areas while applying water more uniformly. This design not only enhances water conservation but also minimizes the time and effort needed for effective irrigation.

Applying rotary nozzles effectively involves recognizing their unique applications. They are particularly beneficial in areas with high water needs, such as flower beds and vegetable gardens, where even distribution is vital for plant health. These nozzles are also ideal for slopes and uneven terrains, as their ability to adjust the spray radius allows for better absorption and reduced runoff. Moreover, incorporating rotary nozzles into existing irrigation systems can lead to improved water efficiency and the promotion of sustainable practices. Proper selection and installation will result in healthier landscapes and enhanced resource management, demonstrating the importance of understanding the fundamentals behind rotary nozzles.

When selecting a rotary nozzle, several critical factors come into play to ensure optimal performance and efficiency. Firstly, consider the application of the nozzle. Different tasks require varying spray patterns and coverage areas. For instance, a nozzle designed for landscaping might have different specifications compared to one intended for industrial cleaning. Understanding the intended use will guide the selection towards a nozzle that delivers precise coverage and meets the required pressure specifications.

Another essential factor is the material composition of the nozzle. Durable materials can enhance longevity and resist wear, especially in high-pressure environments. Additionally, the nozzle's flow rate and angle of spray are crucial for achieving the desired results. A nozzle with adjustable settings may offer versatility for different tasks, allowing users to customize the spray pattern based on specific requirements. Ultimately, evaluating these factors will help in making an informed decision that maximizes effectiveness and efficiency in various applications.

When installing and setting up rotary nozzles, it is crucial to prioritize precise alignment and elevation for optimal performance. According to industry reports, improperly installed nozzles can lead to over-watering and inefficient water use, significantly affecting landscape health. To avoid common pitfalls, ensure that the nozzles are level with the surrounding turf and not obstructed by any foliage. This is particularly important because a slight misalignment can cause water to miss essential areas, resulting in uneven irrigation and potential plant stress.

In addition to proper positioning, the setup of rotary nozzles should include adequate spacing based on their manufacturer recommendations. Studies indicate that maintaining appropriate distances—typically between 10 to 15 feet—between rotating nozzles can enhance water distribution uniformity. This spacing enables water to overlap effectively, ensuring that each area receives the necessary hydration without creating dry spots. Furthermore, pressure settings should be monitored, as rotary nozzles generally operate best at specific pressure ranges (often between 30-50 PSI) to function efficiently. Proper installation and setup fundamentally influence the overall effectiveness of irrigation systems, translating to healthier landscapes and increased water conservation.

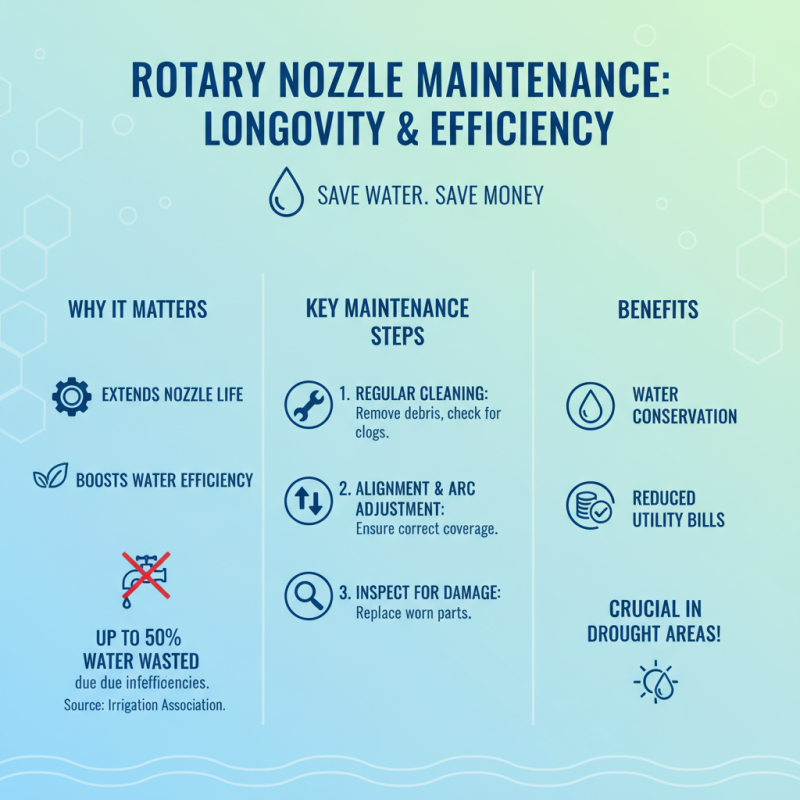

Maintaining rotary nozzles is essential for ensuring their longevity and performance in irrigation systems. Regular maintenance not only extends the life of the nozzles but also enhances the efficiency of water usage, which is particularly crucial in drought-prone areas. According to a report by the Irrigation Association, improper maintenance can lead to significant water waste, estimating that up to 50% of irrigation water is lost due to system inefficiencies. Therefore, implementing best practices for upkeep is vital.

One of the most effective maintenance practices is to regularly inspect and clean the nozzles. Build-up of dirt, mineral deposits, or debris can obstruct water flow, reducing coverage efficiency. It is recommended to inspect nozzles every three months, especially in areas with hard water or high sediment levels. Additionally, using a gentle brush or cloth to clean the nozzles can prevent long-term wear caused by abrasive particles. Furthermore, replacing worn or damaged nozzles promptly can save resources and enhance system performance, as a study by the American Society of Agricultural and Biological Engineers indicates that proactive maintenance can improve irrigation efficiency by up to 30%.

Another important aspect of maintenance is to ensure proper installation and alignment of the rotary nozzles. Misalignment can cause uneven water distribution, leading to wet or dry spots in the landscape and further necessitating adjustments or repairs. Industry standards suggest that nozzles should be positioned at the correct height and angle to ensure optimal performance and longevity. Regular training for operators on these best practices can significantly decrease the incidence of maintenance-related issues and improve overall irrigation effectiveness, contributing to sustainable water management practices in landscape maintenance.

When using rotary nozzles, avoiding common mistakes can significantly enhance performance and efficiency. One frequent error is neglecting the correct flow rate. A study by the Irrigation Association indicates that improper flow rates can reduce water savings by up to 30%. It's crucial to ensure that the nozzle's specifications align with the system’s overall design—all while considering the specific landscaping needs. Understanding these parameters not only prevents waste but also prolongs the lifespan of irrigation equipment.

Another common pitfall is misalignment during installation. Misaligned nozzles can cause uneven water distribution, leading to overwatering in some areas and underwatering in others. Research by the American Society of Agricultural and Biological Engineers shows that a mere 5% misalignment can diminish irrigation efficiency by 15%. Regular checks and adjustments to the angle and position of rotary nozzles can maintain their intended purpose and optimize water usage. Moreover, keeping the nozzles clean and free of debris is essential, as clogged nozzles can exacerbate these issues and contribute to unnecessary water waste.

| Tip Number | Tip Description | Common Mistakes |

|---|---|---|

| 1 | Choose the right nozzle size for your application | Using a nozzle that is too large or too small |

| 2 | Select the appropriate pressure settings | Setting pressure too high can damage plants |

| 3 | Adjust nozzle angle for optimal coverage | Leaving nozzles angled incorrectly |

| 4 | Clean nozzles regularly to prevent clogs | Neglecting maintenance can reduce efficiency |

| 5 | Use rotary nozzles in suitable conditions | Using them during high winds can lead to uneven application |

| 6 | Consider soil type when choosing nozzles | Ignoring soil absorption rates can cause runoff |

| 7 | Monitor water usage and adjust settings accordingly | Failing to track water usage can lead to waste |

| 8 | Test different nozzles to find the best fit | Not experimenting with options can limit effectiveness |

| 9 | Utilize manufacturer guidelines for best practices | Ignoring guidelines can lead to improper use |

| 10 | Seek professional advice when uncertain | Avoiding consultation can result in poor performance |